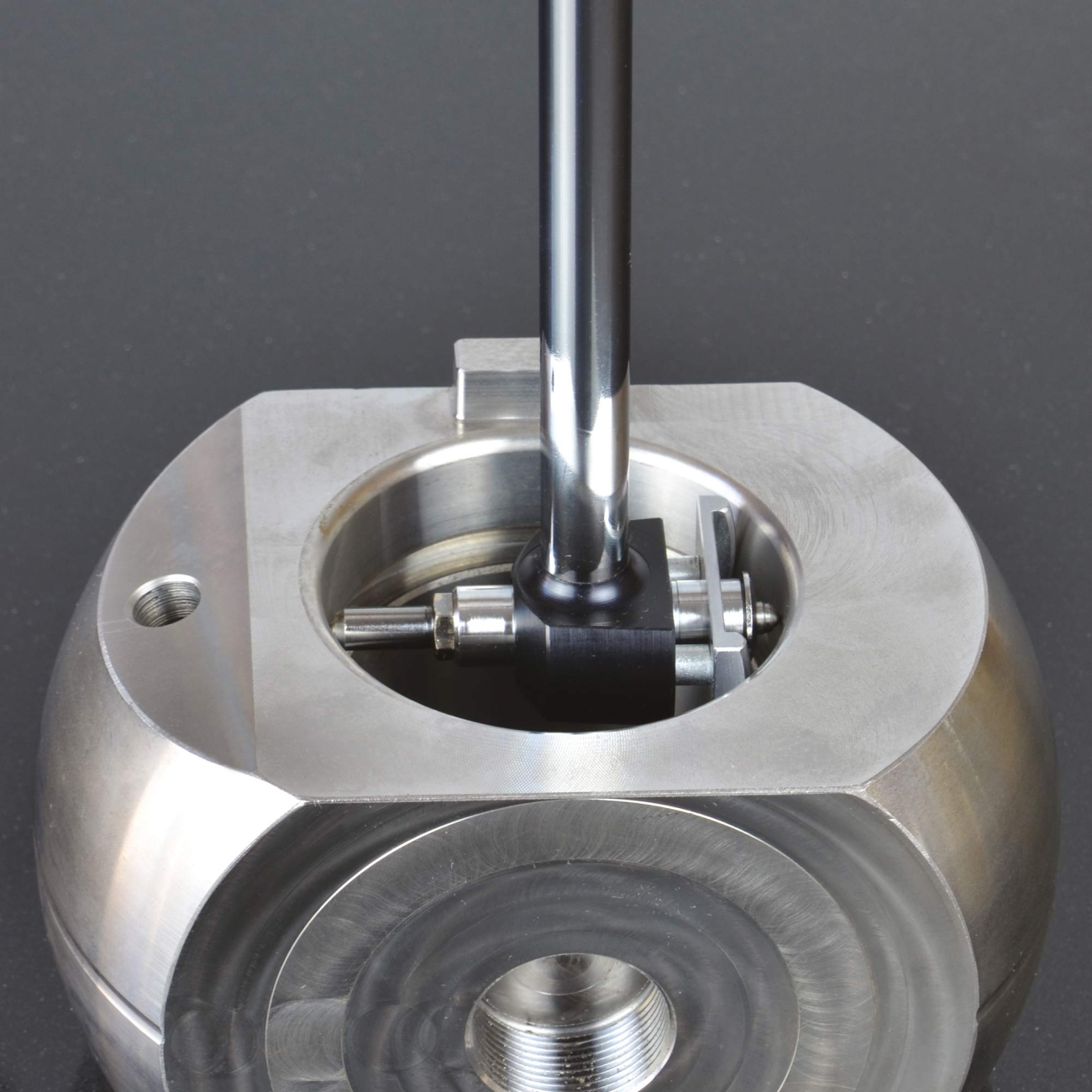

A reamer is an instrument used for measuring ovality and taper and for checking inside diameters of circular holes, particularly extra small, small, blind, and deep holes. Reamers designed for measuring extra-small holes are precision instruments that allow fast but very accurate measurements. The design of these bore gauges requires that the contact elements have a very large radius of curvature so that they can be easily placed inside the hole, align with the axis of the hole, and thus provide the actual diameter measurement. Bore gauges designed for measuring small holes, on the other hand, due to the special construction of the head, can self-center in the holes, providing maximum convenience in use, as well as high levels of accuracy.

Showing all 13 results